In today’s fast-paced business landscape, effective inventory management is crucial for ensuring smooth operations and maximizing profitability. From small businesses to large enterprises, every organization deals with inventory in some form or another. Whether it’s raw materials, finished products, or supplies, managing inventory efficiently can make or break a company’s success.

Understanding Inventory Management

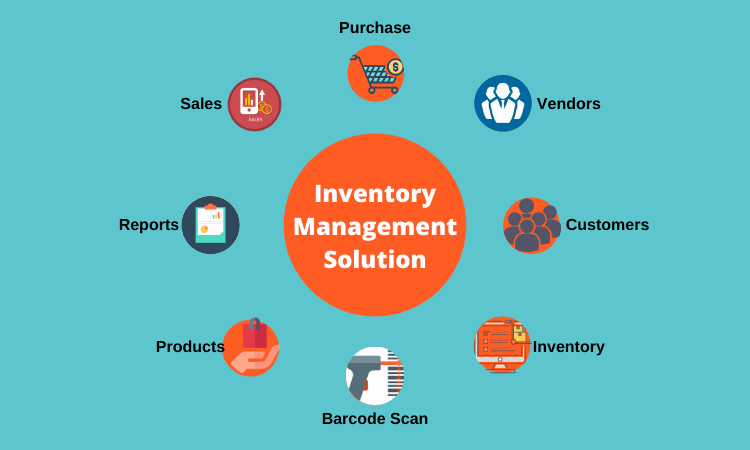

Inventory management refers to the process of overseeing and controlling the flow of goods in and out of a company’s inventory. It involves tracking inventory levels, monitoring stock movements, and optimizing inventory turnover to minimize costs and maximize revenue. Effective inventory management requires a balance between ensuring sufficient stock levels to meet customer demand and avoiding excess inventory that ties up capital and storage space.

Key Components of Inventory Management

- Inventory Tracking Systems:

Implementing an efficient inventory tracking system is essential for keeping tabs on inventory levels in real-time. Whether it’s through barcode scanning, RFID technology, or inventory management software, businesses can accurately monitor inventory movements from receiving to shipping. - Demand Forecasting

Anticipating customer demand is a crucial aspect of inventory management. By analyzing historical sales data, market trends, and seasonal fluctuations, businesses can forecast demand more accurately and adjust their inventory levels accordingly to prevent stockouts or overstock situations. - Inventory Optimization

Optimizing inventory involves finding the right balance between maintaining adequate stock levels and minimizing carrying costs. Techniques such as ABC analysis, economic order quantity (EOQ), and just-in-time (JIT) inventory management help businesses optimize their inventory levels and reduce excess inventory holding costs. - Supplier Management

Building strong relationships with suppliers is vital for ensuring a reliable supply chain. Effective supplier management involves negotiating favorable terms, maintaining open communication, and collaborating on inventory planning to minimize lead times and ensure timely deliveries.

Benefits of Effective Inventory Management

- Improved Efficiency

Efficient inventory management streamlines operations and reduces inefficiencies by ensuring the right products are available at the right time and in the right quantities. This leads to faster order fulfillment, reduced stockouts, and improved customer satisfaction. - Cost Savings

By optimizing inventory levels and reducing excess inventory, businesses can lower carrying costs associated with storage, handling, and obsolescence. Additionally, better inventory management can help minimize stockouts and lost sales, preventing revenue losses and improving overall profitability. - Enhanced Customer Service

Timely order fulfillment and accurate inventory tracking contribute to better customer service. With efficient inventory management, businesses can fulfill orders quickly, provide accurate delivery estimates, and avoid backorders, leading to happier customers and repeat business. - Increased Visibility

Comprehensive inventory management systems provide businesses with greater visibility into their supply chain processes, allowing them to identify bottlenecks, track inventory movements, and make data-driven decisions to optimize operations.

Fulfillment Solutions and Inventory Management

Fulfillment solutions play a critical role in inventory management by handling order processing, picking, packing, and shipping tasks on behalf of businesses. Outsourcing fulfillment services to third-party logistics (3PL) providers can offer several benefits, including:

- Scalability

Fulfillment solutions can scale operations according to fluctuating demand, allowing businesses to flexibly adjust their inventory levels and fulfillment processes without investing in additional infrastructure or manpower. - Expertise

3PL providers specialize in logistics and fulfillment, bringing expertise and experience to the table. By leveraging their knowledge and resources, businesses can improve efficiency, reduce errors, and focus on core activities. - Cost Savings

Outsourcing fulfillment can lead to cost savings by eliminating the need for warehouse space, equipment, and labor. Additionally, 3PL providers may have negotiated shipping rates and bulk discounts, further reducing fulfillment costs. - Global Reach

Fulfillment solutions can help businesses expand their reach to new markets by offering international shipping and distribution services. By leveraging a global network of warehouses and carriers, businesses can efficiently serve customers worldwide.

Inventory Management Techniques

- Just-in-Time (JIT) Inventory

JIT inventory management focuses on minimizing inventory levels by only ordering or producing goods as they are needed. This approach reduces holding costs and minimizes the risk of excess inventory. However, it requires careful coordination with suppliers and a reliable supply chain to ensure timely deliveries. - First-In, First-Out (FIFO)

FIFO is a method of inventory management where the oldest inventory items are sold or used first. This ensures that perishable or time-sensitive goods are consumed before newer items, reducing the risk of spoilage or obsolescence. - Batch Tracking

Batch tracking involves assigning unique identifiers or batch numbers to groups of products to track their movement and expiration dates. This technique is particularly useful for industries such as pharmaceuticals and food manufacturing, where product traceability is essential for compliance and safety. - Cross-Docking

Cross-docking is a logistics strategy where incoming goods are directly transferred from inbound to outbound transportation vehicles with minimal or no storage time in between. This technique reduces handling and storage costs and speeds up order fulfillment, especially for fast-moving products.

Challenges in Inventory Management

- Demand Variability

Fluctuations in customer demand can pose challenges for inventory management, leading to stockouts or excess inventory. Businesses must implement robust demand forecasting techniques and agile inventory management strategies to adapt to changing market conditions effectively. - Supply Chain Disruptions

Disruptions in the supply chain, such as natural disasters, labor strikes, or geopolitical events, can disrupt inventory flows and lead to delays or shortages. Businesses need contingency plans and alternative sourcing strategies to mitigate the impact of supply chain disruptions on inventory management. - Inventory Obsolescence

Products may become obsolete due to changes in consumer preferences, technological advancements, or regulatory changes. Managing obsolete inventory poses a financial risk for businesses, as it ties up capital and storage space. Implementing inventory rotation strategies and offering discounts or promotions can help minimize the impact of inventory obsolescence. - Inventory Accuracy

Maintaining accurate inventory records is essential for effective inventory management. Inaccuracies, such as stock discrepancies or miscounts, can lead to fulfillment errors, stockouts, and customer dissatisfaction. Implementing inventory control measures, such as regular stock audits and barcode scanning, can improve inventory accuracy and reliability.

Future Trends in Inventory Management

- Automation and Robotics

Advances in automation and robotics technology are transforming inventory management processes, enabling faster order fulfillment, accurate picking, and reduced labor costs. Automated warehouse systems, such as automated guided vehicles (AGVs) and robotic picking systems, are becoming increasingly common in modern warehouses. - Artificial Intelligence (AI) and Machine Learning

AI and machine learning algorithms are being used to analyze vast amounts of data and optimize inventory management decisions. Predictive analytics can forecast demand more accurately, while AI-powered inventory optimization tools can recommend optimal stocking levels and replenishment strategies. - Blockchain Technology

Blockchain technology is being explored for its potential to enhance supply chain transparency and traceability. By recording transactions in a decentralized and immutable ledger, blockchain can improve visibility into the movement of goods across the supply chain, reducing the risk of counterfeiting and fraud. - Omni-Channel Fulfillment

With the rise of e-commerce and omnichannel retailing, businesses are adopting integrated fulfillment strategies to meet customer expectations for fast and flexible delivery options. Fulfillment solutions that can seamlessly manage orders across multiple sales channels, including online, in-store, and mobile, are becoming increasingly important for retailers.

Conclusion:

In conclusion, mastering inventory management is essential for achieving efficient fulfillment solutions and driving business success. By implementing effective inventory management practices, businesses can improve efficiency, reduce costs, enhance customer service, and gain a competitive edge in today’s marketplace. Whether through inventory tracking systems, demand forecasting, optimization techniques, or outsourcing fulfillment services, investing in inventory management can yield significant benefits for businesses of all sizes.