Crafting custom texture and linen boxes is an elaborate method that starts with a deep knowledge of the brand’s identity and target market. Designers collaborate intently with clients to capture the essence of their brand, translating it into tactile studies that resonate with clients.

Research and Inspiration

The adventure starts with research and concept gathering. Designers immerse themselves within the brand’s aesthetics, exploring its history, values, and visible language. They draw proposals from a myriad of sources, ranging from nature’s textures to architectural marvels, searching for elements that align with the brand’s narrative.

Conceptualization and Sketching

Once armed with the concept, designers start the conceptualization segment, brainstorming ideas and sketching preliminary standards. This degree is characterized using experimentation and exploration, as designers play with extraordinary textures, shapes, and embellishments to deliver their vision to life on paper.

Digital Rendering and Prototyping

With the idea finalized, designers transition to digital rendering, the use of specialized software to create certain mockups of the packaging layout. Digital rendering permits for precise visualization of the way the feel and linen elements will interact with the overall packaging shape.

Prototyping follows digital rendering, wherein bodily samples of the custom packaging are produced for evaluation.

Production and Quality Assurance

Once the prototype is authorized, production starts and evolves. Skilled craftsmen meticulously craft each box, paying interest to every detail to ensure the highest standards of satisfaction and consistency. Throughout the manufacturing process, stringent pleasant guarantee measures are in the region to uphold the integrity of the layout. Each box undergoes rigorous inspection to ensure that it meets the consumer’s specs and exceeds expectations.

Delivering a Seamless Experience

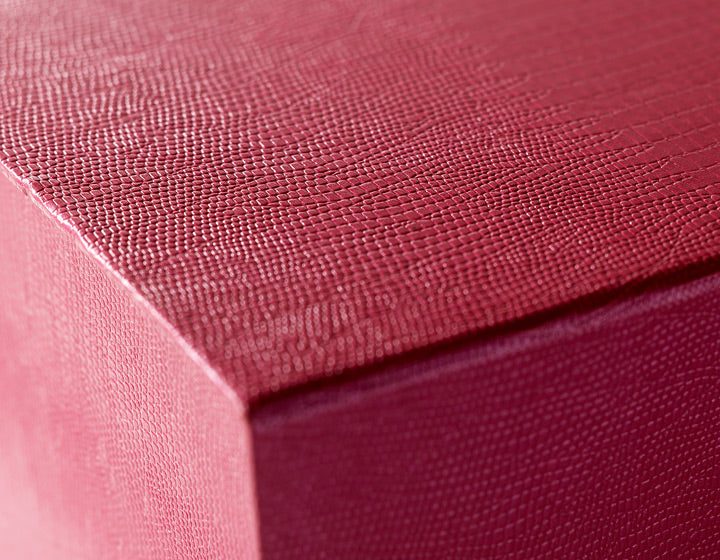

Printed texture and linen packaging offer a unique combination of visible attraction and tactile pleasure. Leveraging present-day printing technology, designers can create stunningly realistic textures that elevate the packaging to a work of artwork.

The Role of Technology in Texture Replication

Advancements in printing generation have revolutionized the replication of textures in packaging design. High-resolution printers can as it should be reproduce tricky textures, from the subtle grain of wood to the delicate weave of linen, with unprecedented fidelity.

Innovation in Sustainable Materials

Designers are continuously exploring innovative methods to beautify the sustainability of texture and linen packaging. From eco-friendly materials to inks and even biodegradable coatings, everything in the production manner is scrutinized to decrease environmental impact without compromising on niceness or aesthetics.

Exploring the Design Process

Crafting custom texture and linen packaging is a tricky system that encompasses numerous degrees, such as layout, printing, completing, and pleasant warranty

- Design and Conceptualization: The adventure starts with an intensive knowledge of the brand’s identification, values, and target market. Designers behavior large research and collect inspiration to inform the conceptualization segment. Sketches and virtual mockups are created to visualize the design, exploring distinct textures, shapes, and embellishments.

- Printing Techniques and Technologies: Once the layout is finalized, it’s time to deliver it to lifestyles through printing. Advanced printing technology, such as offset printing, virtual printing, or silk-display printing, is utilized to replicate complicated textures with precision and readability. Specialized inks and coatings are selected to beautify the tactile and visible enchantment of the packaging.

Finishing Touches: Embossing, Debossing, and Foiling

To elevate the cultured enchantment of texture and linen boxes, designers frequently comprise finishing techniques which include embossing, debossing, and foiling. Embossing creates raised textures, including depth and measurement to the design, while debossing creates recessed impressions for a diffused, sophisticated impact. Foiling provides metallic accents, lending a hint of luxury and refinement to the packaging.

Quality Assurance and Prototyping

Throughout the manufacturing process, rigorous quality guarantee measures are implemented to preserve the integrity of the layout. Prototypes are meticulously inspected to make certain that every texture, print, and end meets the client’s specs and exceeds industry requirements. Any deviations are addressed right away to make certain a wonderful cease product.

Delivering a Seamless Experience

Custom printed boxes provide a harmonious combo of visible beauty and tactile appeal. From the intricacy of the printing technique to the finesse of the finishing touches, each thing is meticulously curated to create an unforgettable unboxing experience.

Innovation and Customization

Innovative printing and completing techniques allow for remarkable customization, empowering manufacturers to create packaging that is as precise as their merchandise. Whether it’s a subtle linen texture or a bold embossed pattern, each detail is tailored to mirror the brand’s persona and resonate with consumers.

Enhancing Brand Perception

Texture and linen boxes serve as tangible expressions of a brand’s identity and values. The tactile enjoyment of interacting with the packaging enhances brand perception, fostering a sense of authenticity and luxury that leaves an enduring impression on clients.